The credit for the discovery of x-rays goes to Sir Wilhem Conrad Roentgen (1845-1923), Professor at Wuerzburg University in Germany. X-rays helps in the production of the image which is captured on a film, may be viewed directly (fluoroscopy) or on a monitor with digital radiology. Initially, a sheet of platinocyanide was used to view the fluorescence produced by X-ray photons followed by the use of photographic plates.

Extraoral films representing large areas of skull and jaws, are exposed placing the film outside the mouth. Currently, two groups of x-ray films are used widely:

- Screen films

- Non-screen films

Both these films are available in various sizes such as-

4 ¾”× 6 ½”

5″ × 7″

6 ½” × 8”

8″ × 10″

6” × 12”

10″ × 12″

Unboxing the extaroral film

Commonly used extraoral films in dentistry are of the sizes 5″ × 7″, 8″ × 10″, as well as panoramic, 5″ × 12″ and 6″ × 12″. They are boxed in with about 50-100 films in a packet. On the outside, the packets are labelled with the type of film, film size, the total number of films enclosed and the expiration date. As the films are not used intraorally and are not in the direct contact of saliva, packets may not be moisture proof but the manufacturer separates each film with a protective paper.

The films are used with the cassettes, with or without intensifying screens. Panoramic and skull radiography uses high contrast medium speed films. Faster films which provide less image detail are used for panoramic radiography. Cephalometric radiography with soft tissue details uses films which provide less contrast and a wider latitude and thus producing a wide range of densities.

Non screen films

The intensifying screens are not used with such films. The emulsion is highly sensitive to the direct x-ray exposure rather than the fluorescent light. These films are not recommended for the dental purposes. These films are much slower and therefore require a longer exposure time but the details of the image obtained on using these films are much sharper.

Screen films

Screen films are used in combination with the intensifying screens, that emit the visible light. The film is held in between the screen, placed on either side inside the cassette. The screen-film combination inside the cassette is pressed firmly in a rigid manner in order to make a closed contact between the fluorescent layers of the screen and the emulsion of the film. Poor contacts often lead to the blurring of the image on the film. The screen films are sensitive to the fluorescent light rather than the direct x-rays.

Extraoral film equipment

The extraoral films are used in combination with the cassettes and the intensifying screens.

Cassette: A special device used to hold the intensifyin

g screen and the extraoral film, is available in various sizes that correspond the screen and the film sizes. Most of the cassettes are rigid except for the panoramic cassette, which may be flexible. Though, the rigid cassettes are expensive but they last longer and also protect the screen from the damage. The chances of incorrect loading of the rigid cassettes are very rare as the film fits appropriately there. However, to load the flexible cassette properly, the film must be placed between the two screens and pushed to the end of the cassettes. The cassettes must be light tight in order to protect the film from any undesirable exposures and also to hold the intensifying screens in perfect contact with the extraoral film. Loss of image sharpness is commonly observed in the absence of proper contacts between the intensifying screen and the extraoral film.

A rigid cassette seems to be a book like container with two aluminium or bakelite leaves which opens and closes at the hinges. The front cover lid is made up of plastic or low density metal which offers a very little resistance to the x-ray beam. The back cover is constructed of heavy metal and lined with lead to absorb x-rays which pass through the enclosed film and reduce backscatter radiation. The intensifying screens are installed inside the front and back covers of the cassette with the film in between the two screens. Loading and unloading of the cassette is carried out in the darkroom. A metal letter ‘L’ or ‘R’ is attached to the front cover of the cassette which helps to orient the finished radiograph.

Intensifying screens

Firstly, let us discuss about a few common terminologies used in relation to the intensifying screens.

Luminescence: It is emission of light from any substance bombarded with radiation and is of two types- fluorescence and phosphorescence.

Fluorescence: Here, the luminescence is excited only during the period of irradiation and will terminate at completion of the X-ray exposure. The phosphors in the intensifying screens produce fluorescence.

Phosphorescence: The irradiated material continues to emit light for a time after cessation of exposure to radiation, i.e., after glow. It leads to continuous production of unwanted images.

In radiology, the luminescence effect is used in two ways-

- Fluoroscopy, i.e., the image is obtained on a fluorescent screen

- Increasing the photographic response of silver halide emulsion.

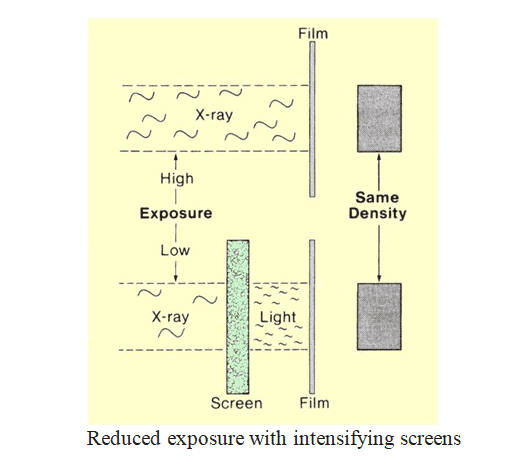

Intensifying screen is a device that transfers the x-ray energy into the visible light, which in turn exposes the screen film. As the effect of the x-rays is intensified, less amount of radiation is required to expose the film which in turn leads to less patient exposure to the radiations. The amount of light emitted is strictly in proportion to the amount of the x-ray energy absorbed which in turn is proportional to the X-ray exposure to which the screen is subjected. Thus, the effect forms the sum total of the x-rays and the visible light emitted by the screens that exposes the x-ray film. Hence, an image receptor that is 10-60 times more sensitive to x-rays as compared to other films is achieved.

Speed of intensifying screens:

The three types of intensifying screens are as follows-

- Standard-slow films

- Rare earth screens- fast screens

- Combination

The fast films uses large crystal size, have the maximum speed but with loss of definition. Small crystal size is used in the slow screens which provide with the best details. The compromise between speed and definition is obtained in medium speed films, which uses the medium sizes crystals.

Composition of the screens:

The intensifying screens are composed of-

- Base- It forms the supporting component for the screen. A stiff cardboard sheet or polyester like material is used to construct a 0.25 mm base approx.

- Reflecting layer- It is a thin layer of white coloured material present in between the base and the luminescent layer. This white colored material is made up of magnesium or titanium dioxide and serves to redirect to the film a large fraction of the emitted visible light which is moving away from the film and which would therefore otherwise be lost. This helps in increasing the sensitivity but unsharpness is produced due to divergence of the light reflected back from the film.

- Phosphor layer- This layer is made up of light sensitive phosphor crystals suspended in a plastic material.

When these phosphor crystals are stuck by photons, they fluoresce. Numerous light photons will get generated even after absorbing a single photon leading to increased film exposure.

The types of phosphors used in the intensifying screens include:

- Crystalline Calcium Tungstate: It fluoresces in the blue portion of the spectrum. The conventional screens (Kodak X-Omatic Regular screens) are used with blue sensitive films.

- Rare earth screens: Terbium-activated gadolinium oxysulphide and Thelium-activated lanthanum oxybromide fluoresce in the green portion of the spectrum. The term ‘rare earth’ implies that the separation of these elements from the earth and also from each other is difficult and not because these are found rarely. Rare earth screens (Kodak Lanex Regular and Medium screens) are designed for use with green sensitive films.

- Coat- The intensifying has to be protected from any mechanical insult including abrasion, scratching and also from any debris or spots. The coat helps in to protect the phosphor layer.

How to increase the film speed??

In the screen-film combination, speed can be increased by some modifications as-

- Use thick phosphor layers

- Conversion efficiency should be high

- Use of higher absorption phosphor

- Decreased resolution of image

The film-screen combination must be matched in order to match the spectral sensitivity of the film with the emission characteristics of the screen.

Effects of using the screens……..

- Unsharpness: The range of unsharpness produced by the screens varies from 0.15 mm for high definition to 0.45 mm for high speed screen. Also, an additional amount of image blurring is produced with the use of screens especially for the screens with higher intensification factor. This can be compensated by reducing the amount of x-ray exposure.

- Mottle: This is the faint irregular pattern of density variations which are not present in the x-ray beam.

- Screen mottle- As the intensification factor varies over the screen surface, the fluorescent layer may show up the non-uniformity

- Quantum mottle- This is in relation to the actual number of x-ray photons reaching the cassette. Faster the film lesser are the x-ray photons reaching the cassette. Quantum mottle is variation in the x-ray intensity over the surface of the screen that becomes apparent on the film.

Care of use of the intensifying screens………

The intensifying screens must be used with utmost care in order to obtain an image. The following factors has to be kept in mind:

- No gap should be left in between the screen and the film. It helps to avoid the image blurring

- Scratches, dust, or grease will prevent the light photons passing from screen to film, and will show a pattern on the film. Hence, this must be avoided.

- Never leave the cassettes open to prevent the dirt enter into it.

Lead intensifying screens

These screens are used only with high kV, i.e. with 250 kV X-rays or cobalt 60 gamma rays. They have very low intensification factor, about 2-3, with a completely different mode of action as compared to that of the ‘salt screens’. Lead screens are always used in pairs but are considerably thinner. The front screen is usually about 0.1 mm (0.004 in) and the back screen 0.15 mm (0.006 in) thick. The thinness of the lead screens impart no additional screen blurring; neither do they suffer from reciprocity failure.

On a concluding note……..

The extraoral radiography using the extraoral films finds its use in imaging the skull, temporomandibular joint along with the jaw bones. The use of intensifying screens along with the extraoral films helps reducing the patient exposure.

The x-rays help to image the internal structures on the film and allowing the dentist to see the hidden issues.

https://waterfallmagazine.com

I go to see each day some web pages and information sites to read articles or reviews, except this weblog offers feature based content.